CATALOGUE TIE ROD CYLINDERS ISO 6020/2

CATALOGUE CYLINDERS ISO 6022

HYDRAULIC CYLINDER COMPACT CATALOGUE

HYDRAULIC CYLINDER ISO 6020/1

AGRICULTURAL HYDRAULIC CYLINDERS - MDA

HYDRAULIC CYLINDERS ISO 3320 - MDR

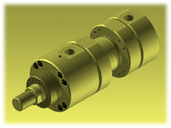

TIE ROD CYLINDERS UNDER ISO 6020/2

(working pressure up to 160bar)

This line of products is subject to ISO 6020/2 which presides over the definition of the standard application, this is a synonym for interchangeability with what is

present on the market. The field of application of choice is the industrial working pressure is 160 bar, which refer to a continuous service, this figure rises to 210 bar for a drive

intermittent. The maximum permissible speed is 0.5 m / sec., The dynamic behavior at low speeds is stable and free of by the "stick-slip". A special version, use dedicated high-speed extends the

application range to the value of 5 m / sec.

The building components are assembled by means of bolts high tensile steel, the tube where the piston slides inside is smooth, the stem is in C45 steel with chromium

thick, the guide elements are in bronze and composite material .

Particular attention is directed to the appearance of seals: the seals are manufactured by a company of world-class, cutting-edge in the aspect of the profile and

the compounds, this is a prerequisite to prevent fluid leakage and increase the overall performance of 'actuator.

The bores are available to climb: the minimum is equal to 25 mm, maximum 200 mm.

For each dimension of the bore are two or three possibilities about the size of the rod, while the proposed anchors consist of 15 versions to meet any installation

on the machine.

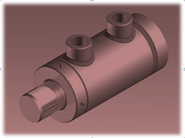

HYDRAULIC CYLINDERS UNDER ISO 6022 - SERIES RR (pressures up to 250 bar)

This line of products is subject to the standard ISO 6022 that governs the definition of the standard application, this is a synonym for interchangeability with what is present on the market. The field of application of choice is the industrial, in a severe operating environment such as the presence of vibration, pulsating pressure, high cycle frequency, consisting of mechanical stress and high radial loads. The operating pressure is 250 bar, which refer to a continuous service, this figure rises to 350 bar for a drive intermittent. The maximum permissible speed is 0.5 m / sec, the dynamic behavior at low speeds is stable and free of by the "stick-slip". A special version, use dedicated high-speed extends the application range to the value of 5 m / sec. The building components are assembled by means of threads and screws in high-strength steel, the tube where the piston slides inside is smooth, the stem is in C45 steel with chromium thick, the guide elements are in bronze and material composite. Particular attention is paid to the appearance of the seals: seals are produced by a company of world-class, cutting-edge in the aspect of the profile and the compounds, this is a prerequisite to prevent fluid leakage and increase the overall performance of 'actuator. Under this aspect it should be noted the presence of a special version to extreme operating conditions, which, however, limits the maximum speed at 0.3 m / sec. The bores are available to climb: the minimum is equal to 50 mm, maximum 320 mm. For each dimension of the bore are two possibilities about the size of the rod, while the proposed anchors consist of six versions to meet any installation on the machine, including the solutions to the flange.

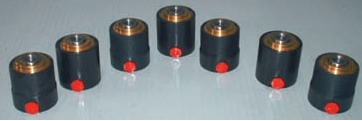

HYDRAULIC CYLINDER COMPACT (for short stroke clamping devices)

This type of cylinder, very compact and with short stroke, are mainly dedicated to asservire locking devices. The maximum pressure is 400 bar, while the maximum speed is of the order of 1 m / sec. The bores are seven available, the minimum is 20 mm, and the maximum is 100 mm. The standard stroke is divided into two fields: 25 mm and 50 mm, in each mode are available stroke values intermediate between 1 mm and 50 mm. The cylinders are arranged both for fixing a vertical axis as well as horizontal. The project includes: steel body, steel stem and piston guide and bronze seals compact high speed. For heavy duty applications such as the presence of high acceleration, high frequency cycles, hostile environments, and difficult to access, there are versions with rod and piston monobloc heat treated.

CILINDRI OLEODINAMICI SPECIALI (a disegno su specifica del cliente)

This product line is subject to the specific use prescribed by the client, then the project is developed according to the final destination. The field of application is the industrial sector, in a severe operating environment such as the presence of vibration, pulsating pressure, high cycle frequency, consisting of mechanical stress and high radial loads such as presses, servo systems for the steel industry, aluminum processing, industry mining, shipbuilding, large civil works sector. The maximum operating pressure in continuous service is 350 bar, while the project takes on a safety factor to functional application. In the field of presses have been developed very demanding applications, with excellent results, this both in terms of ease of installation, performance, reliability and easy maintenance. Where necessary, can be dealt with particular problems such as: constructive solution to operate in aggressive environments, the use of special materials for weight reduction.

The range of accessories configures all types of rod end greasable hinges and forks. Another strength is the ability to choose, without any particular problems of order management, special versions relating to the braking limit, the terminal stem, anchor, to monitor the position of the rod, to systems of non-rotating piston rod inside the cylinder, or even to use in particular environments. By way of further information, remind the availability of functional modules dedicated to apply directly to the cylinder without the use of fittings or other elements. It is a project developed on their own, that meets the safety standards around the block in position and control the movement of the movable element actuated by the hydraulic cylinder, also may be implemented other functions such as speed control, even with the rapid cycle -slow and control the acceleration and deceleration technique using proportional representation. For most of the versions is possible to implement the position control devices, such as transducers and sensors stroke end: in this way is also satisfied the use in technical systems with advanced automation.